China Plywood Machine Manufacturer Linyi Guoyu Machinery Co.,Ltd

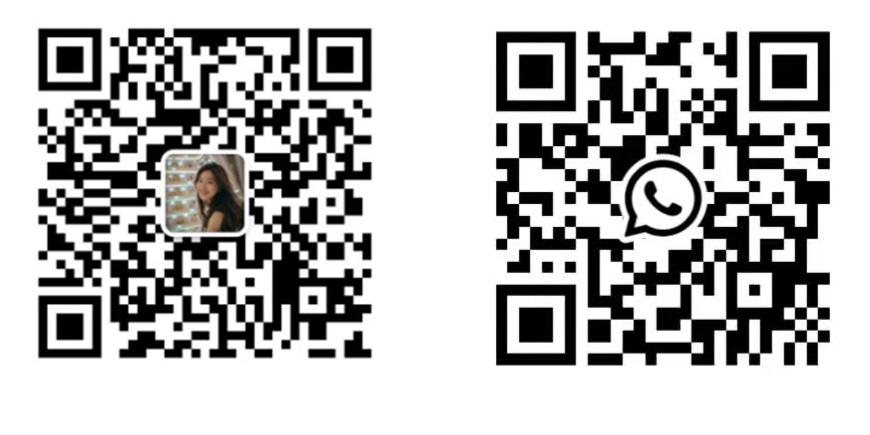

Luna Jiang

+86 13385391681

Luna Jiang

+86 13385391681

Hot press is a very wide range of machinery, it can be said that, and plate related industries, nine out of ten will be involved in hot press, although the application of hot press is so extensive, it is precisely because of such a wide application that some people do not know the danger of hot press. Next, let's take a look at how to operate the hot press correctly and safely.

Turn on the power supply, set the temperature control system of the hot press according to the processing temperature of the workpiece. After the temperature control setting is completed, start the heat transfer oil circulating pump switch and heat transfer oil heating control switch, and the press temperature control system starts. Take off the protective cover of the time relay panel for the pressure holding timer, and set the pressure holding time of the press according to the requirements of the pressing time of the workpiece in the production process. If the processed parts of the press are skewed in the press, they should be straightened with long wooden strips; in the pressing and closing project of the press, the operators should not touch the pressing plate, and it is strictly forbidden to leave the post. Pay close attention to the working conditions of the equipment and the pressure of the processing parts between the pressing plates. If there is any abnormality, the closing should be stopped immediately. It is strictly forbidden to touch the workpiece or pressing plate and closed mechanical transmission parts with hands in the pressing plate closing project, so as to prevent extrusion and scalding accidents.

For the danger of hot press, we should have some understanding of it, try to avoid the occurrence of dangerous accidents, safe operation.